Matrix diameters up to 1,440 mm pose no problem for us. Additionally, our delivery program includes dies and die sleeves, as well as wear and reinforcement rings, and the refurbishment (grinding and reaming) of molds.

We supply ring dies for all pellet presses.

Especially under high loads, our dies demonstrate the quality you expect. This is the result of an experienced and well-coordinated team, cutting-edge manufacturing methods, and the entire value chain in-house.

It’s the small things that make the big difference. Particularly in hardening, we can apply our entire expertise, ensuring you receive a die with maximum concentricity and optimal hardness in terms of break resistance and service life.

Our dies are exclusively deep-hole drilled and run in. The result is precise and smooth pressing channels that can be put into operation immediately by you, without any running-in time.

During the final inspection, all dies are checked for dimensions and concentricity accuracy. Running in the die is a standard practice for us. Only when all pressing channels are optimally run-in, the die is released for shipping. It’s important for us that the die delivers full performance from the beginning once it’s in your hands.

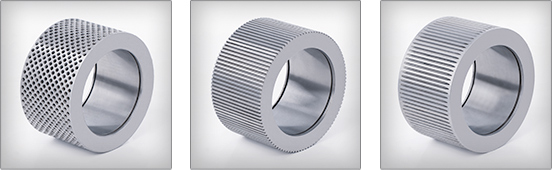

Similar to our approach with dies, we prioritize quality in our roller shells. Maximum concentricity ensures a long lifespan of the press roller bearings and low-vibration operation of the pellet press. The bearing seat in the roller shell is ground to ensure optimal bearing fit.

Punched, grooved with open or closed ends, as well as angled grooving. With us, you’ll find the appropriate roller shells for every machine and process.

Our standard material is C50, and for more demanding use, we recommend roller shells made from 100Cr6.

Benefit from our wear and reinforcement rings, precisely tailored to the dies. We deliver complete rollers for many types of presses in the usual GRAF quality.

Requirement

The quality of a die is evident right from the blank. We have strict requirements for the material of the blanks, the drilling and hardening processes, as well as the final inspection.

Machines

Our machinery is carefully calibrated and partially developed in-house. The CNC lathes are customized to our needs. Our deep hole drilling machines, where our experience is incorporated, ensure the precision of our pressing channels. In the vacuum hardening facilities and during the final finishing of the dies, our products are processed according to your requirements.

Manufacturing

All processes in our manufacturing are coordinated. Each piece is inspected after every step, ensuring top quality ‘Made in Germany.

Unfortunately, there are currently a lot of misunderstandings. We would therefore like to inform you that GRAF GmbH Pressformen in Heddesheim continues to exist unchanged. GRAF GmbH Pressformen has not been sold and nothing has altered. As usual, you can obtain all dies and spare parts for your press from us.

Only GRAF Equipment GmbH in Constance, which was founded a few years ago and whose owner and managing director was Mr Jürgen Joachim, was sold by him to CPM and no longer exists in this form. GRAF Equipment GmbH was a manufacturer of pelletising presses and not of dies.

The sale of GRAF Equipment GmbH has no effect on the business relationship between you and GRAF GmbH in Heddesheim.